Contributing to the development of automotive and IoT sensing technologies

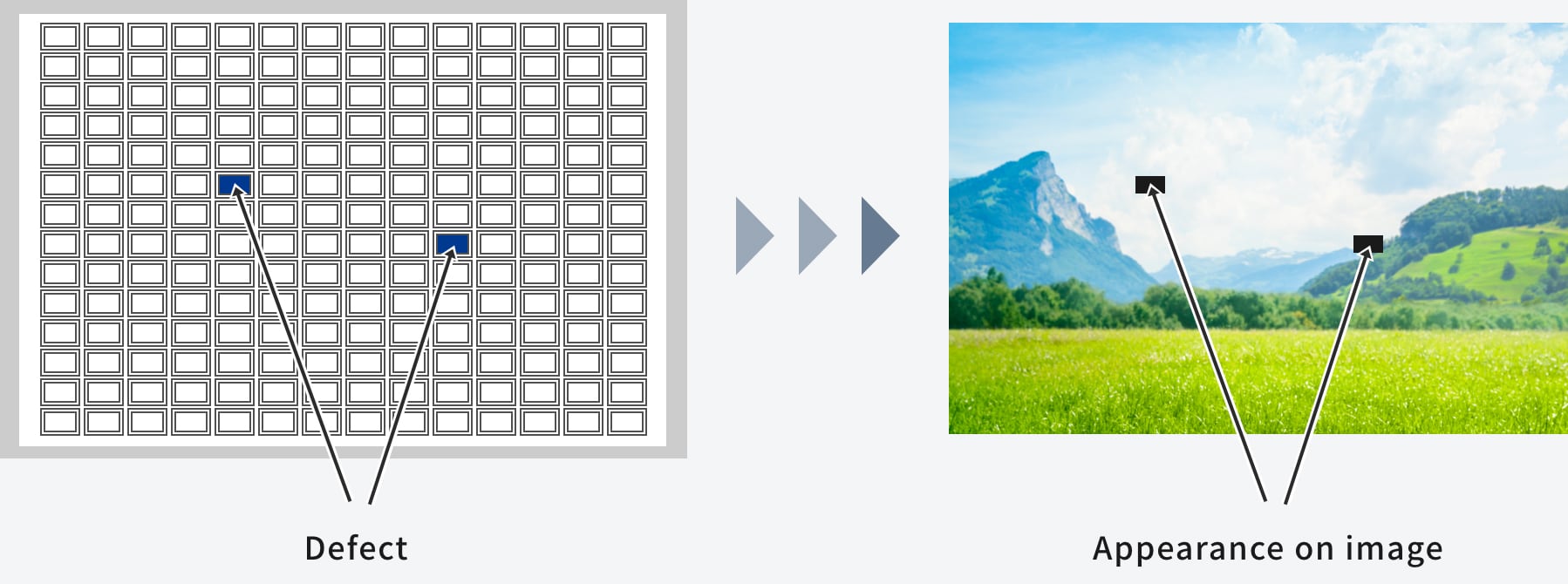

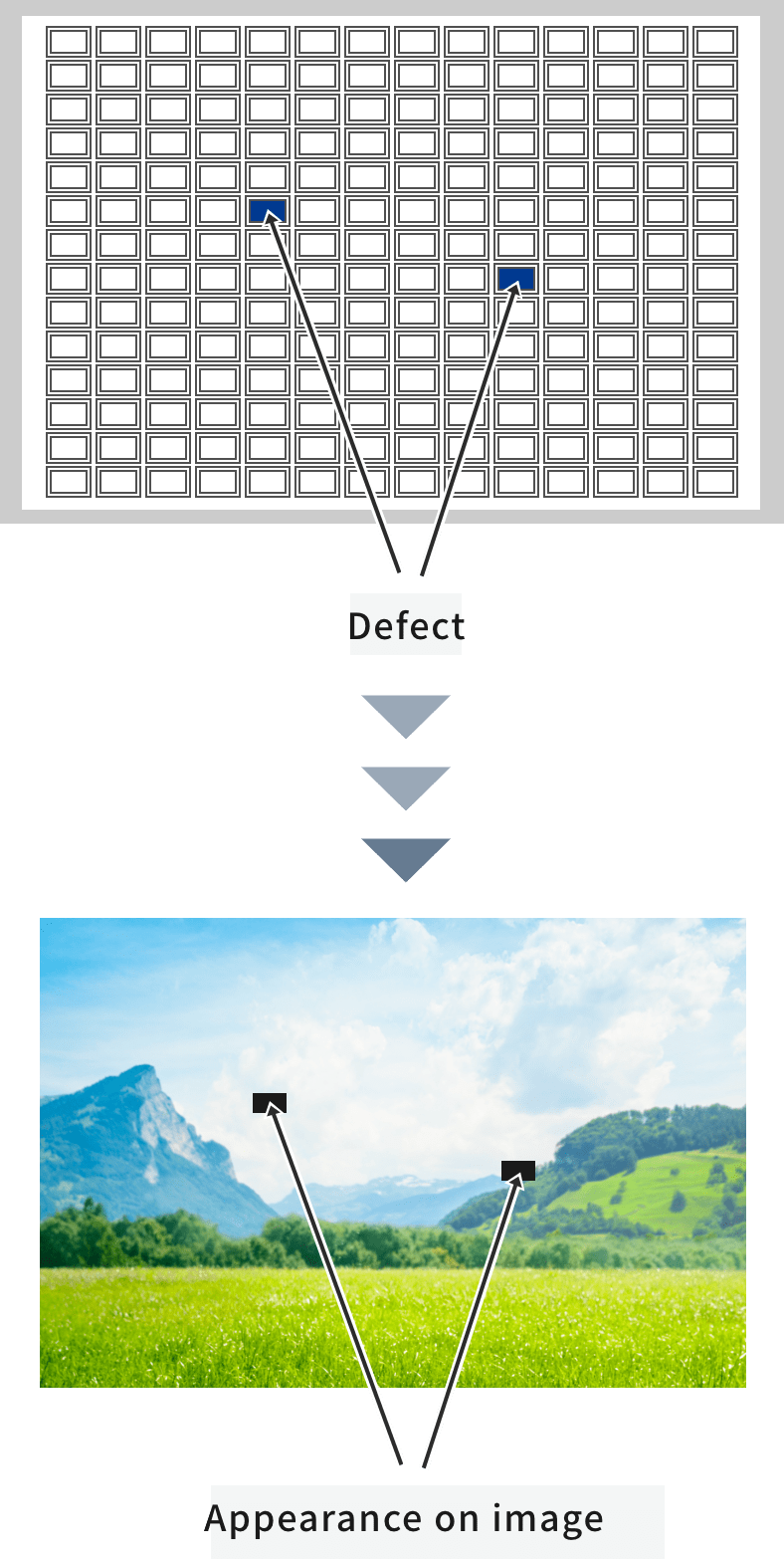

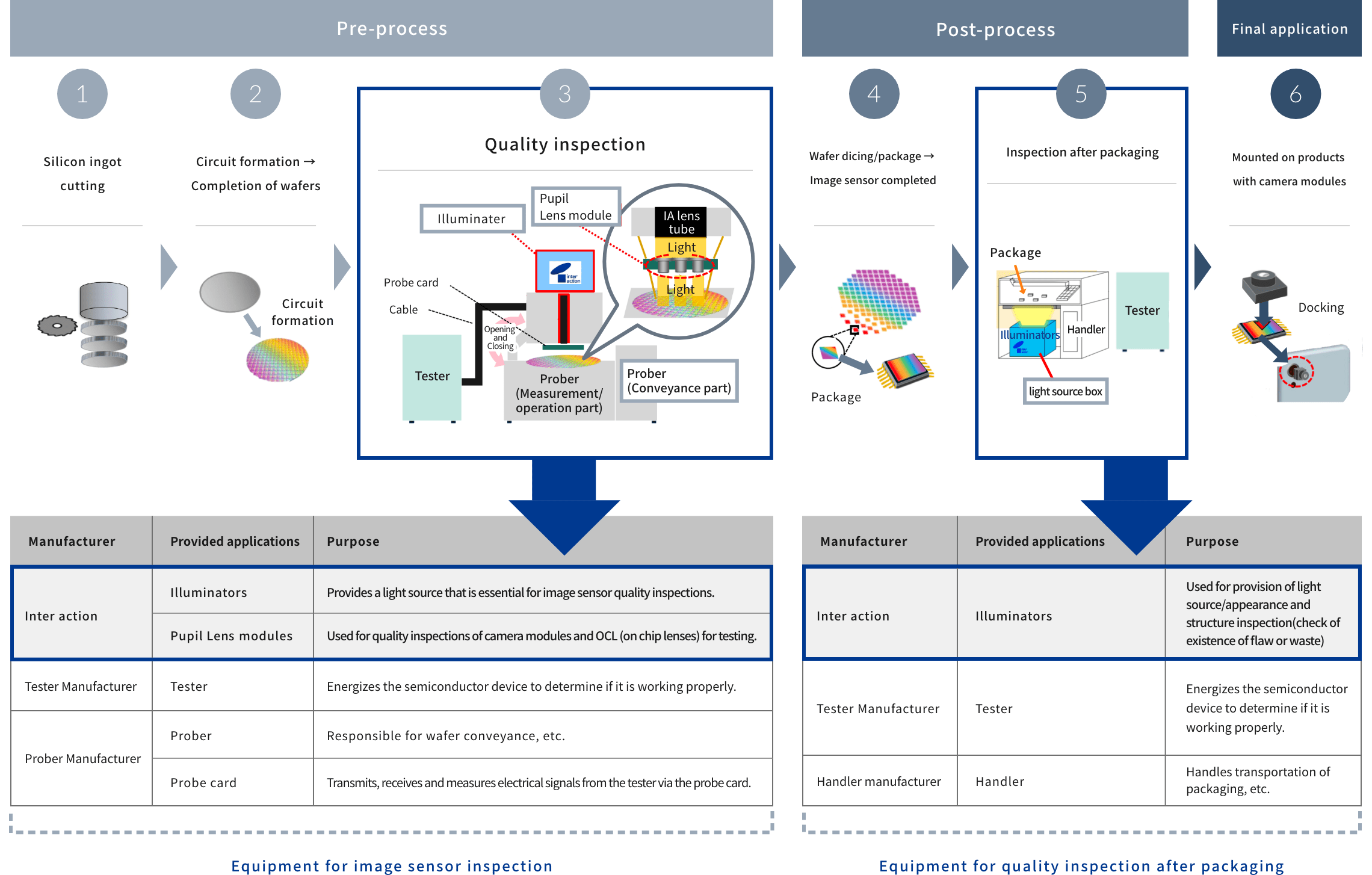

Our main products are illuminators and Pupil Lens Modules®: inspection equipment and devices essential for manufacturing CCD and CMOS image sensors. These devices can identify defects and specifications of image sensors at an early stage, reducing manufacturing costs, improving yields, and guaranteeing the quality of image sensors.

Defects are detected by measuring whether a normal electrical signal is output from the image sensor with respect to the light emitted from the illuminator. Our illuminators are tailor-made to each customer’s request.

The strength of our illuminators is that we offer effective solutions to customers’ problems through a comprehensive and persistent approach that includes mechanical and electrical technology in addition to optical technology. Our technology and customer service are highly rated, and we possess the world’s top share in illuminators.

Although the PLM® is not an essential product for conventional quality inspection, it contributes significantly to improved yield and stable quality. The PLM® is an INTER ACTION original product and our main product after illuminators.

About CCD and CMOS image sensors

What is an image sensor?

An image sensor is a semiconductor that converts light (images) captured from a lens into an electrical signal. In terms of the human eye, an image sensor would be the retina. Its performance greatly impacts the image quality of photographs taken with equipment such as digital cameras.

Image sensor manufacturing process

CONTACT

FIELDS